| 品牌名稱: | Baublies |

| 産品經理: | 楊先生 / Arvin |

| 電話: | 0755 - 8384 2073 18697965101 |

| 傳真: | 0755 - 8384 2050 |

| 電郵: | baublies@euro-me.com |

| 國(guó)外(wài)網址: | www.baublies.com/en… |

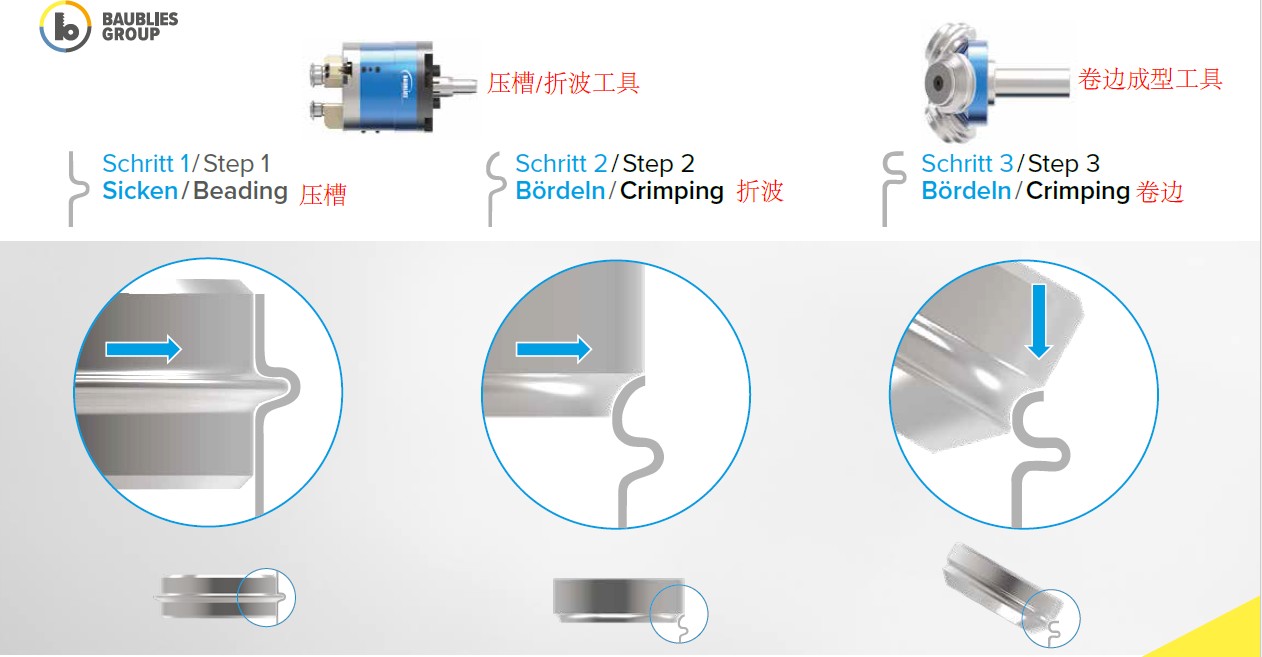

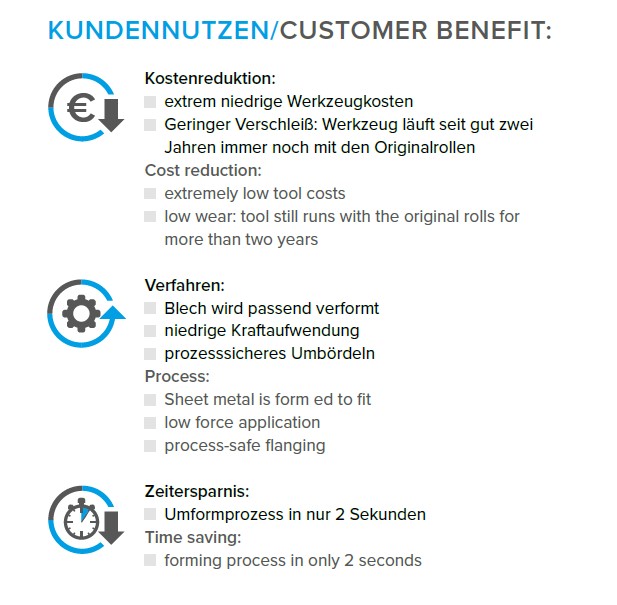

E-MOBILITY:德國(guó)寶力士(Baublies)為(wèi)新能(néng)源車電池電芯制造行(xíng)業開(kāi)發的成型工(gōng)具,電動汽車:三步搞定電池電芯成型工(gōng)藝。

E-MOBILITÄT: UMFORMPROZESS VON BATTERIEZELLEN IN DREI SCHRITTEN

點擊下(xià)方鏈接可(kě)觀看(kàn)相關視(shì)頻(pín):

https://www.baublies.com/media.html

您還可(kě)以登錄我司官網了(le)解pro_class-30_128-30_128.html 更多信息,歡迎來電來函索取詳細資料,共商業務合作(zuò)!

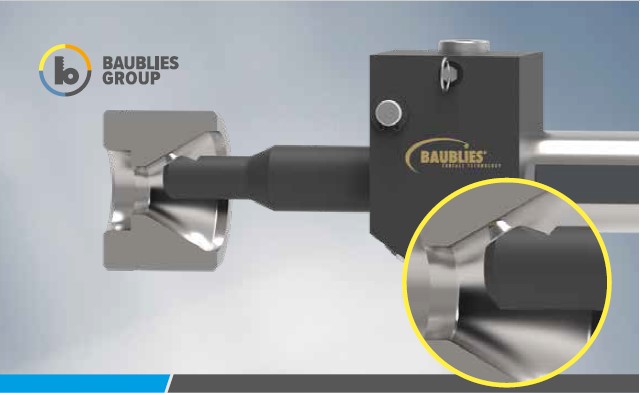

FORMING TOOL

TASK:

<The mixing knife in Vorwerk‘s Thermomix combines the support disc and ground

blades with the M6 nut screwed on and fixed in place using the tumbling method. A sheet metal cap is to make the design food safe and dishwasher safe.

<Batch size 1.5 million pieces per year.

<No lubricant is to be used.

SOLUTION:

<A forming process with a flanging tool from Baublies suitably deforms the shee tmetal and fixes the machined parts: The sheet metal cap, which is flanged in two seconds, makes the design food-safe and dishwasher-safe.

<Forming rollers made of heat-treated tool steel.

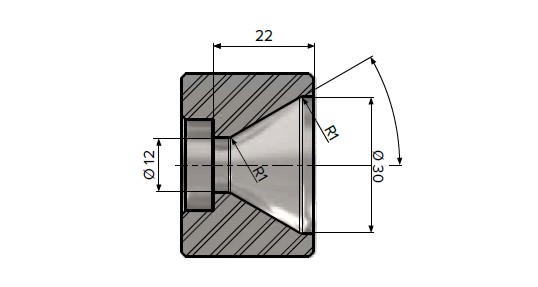

SINGLE ROLLER BURNISHING TOOL

TASK:

<Strengthening of axle journals for heavy commercial vehicles.

<Due to the high load, the transition from the bearing area to the end face of theaxle journal has high requirements for safety against cracking.

<The service life of the components is specified in at least 80,000 cycles.

SOLUTION:

<Deep rolling with single roll tool with base body

<Deep rolling process with forces of 5 kN

<Speed: 50m/min

<Feed rate 0,1 mm/rev

DIAMOND BURNISHING TOOL TASK: <Smoothing of a plasticizing unit/cylinder with an inner diameter Ø12 mm for injection molding machines. This creates a good flow rate of heated plastic.

<Challenge: There is high wear of the surface due to heat

<Material of the component: solid tempered steel.

SOLUTION:

<Baublies diamond burnishing tool for internal machining with base body suitable for hard surfaces HRC > 60

<with adapted diamond holder

<with smoothing diamonds form E

<with spring in tool body

<use on turning-milling center

<Machining: soft machining

– Speed VC 100 m/min

– Feed 0.07 mm/rev.

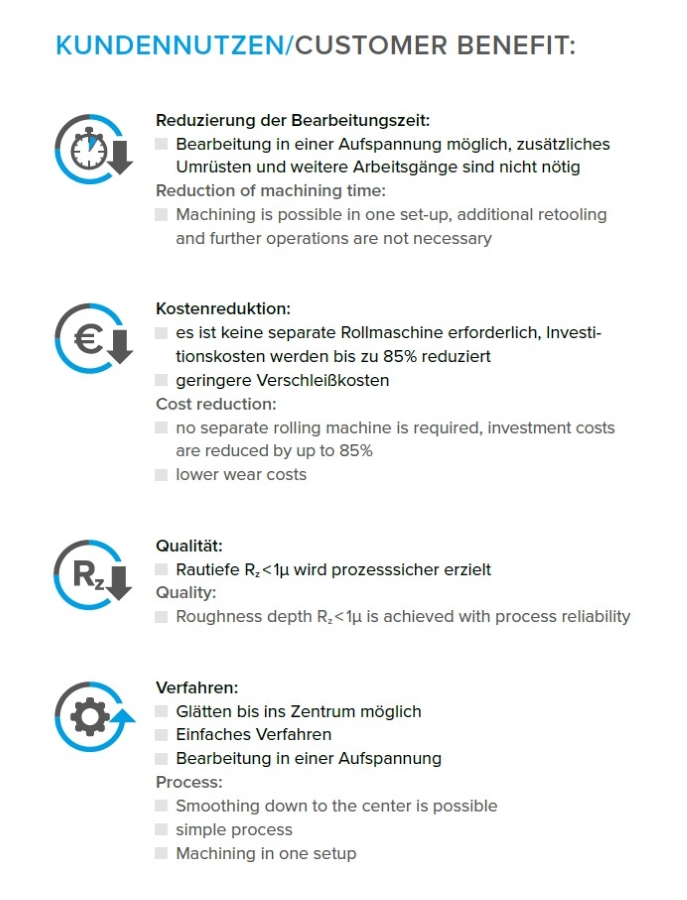

BALL BURNISHING TOOL

TASK:

<Burnishing of a forged ball pin with Ø20-35 mm.

<Large series: number of pieces from 300.000-500.000 pieces

<High demand on surface quality (Rz < 1μ) of the machined ball

<Noise should be avoided

SOLUTION:

<Adapted ball burnishing tool from Baublies with defined geometry(adapted angle).

<For use on lathes with driven tools.

其他(tā)典型應用案例:

氣缸活塞杆滾光(guāng)方案

閥芯滾光(guāng)方案

液壓缸滾光(guāng)方案

動車車軸滾光(guāng)方案

如(rú)有具體需求請(qǐng)直接與産品經理聯絡。