Bucket Elevators are an economical means of elevating bulk raw materials, typically straight up at 90 degrees before discharging the material at the head of the elevator.

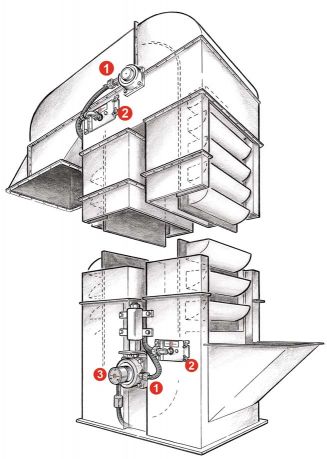

Electro-Sensors provides a line-up of hazard monitoring products designed to keep your equipment and employees safe. There are three critical areas to monitor on a bucket elevator to reduce the risk of a dust explosion.

1. Bearing Temperature Monitoring - Our bearing temperature sensors are 2-wire, loop-powered, and provide a 4-20 mA analog output. Included is an attachment probe, sensor and signal conditioner. The TT420Z-LT (1/2") screws into a 1/8" NPT grease fitting tap and provides a grease fitting for bearing lubrication and a compression fitting for setting probe depth. Sensor is FM approved, dust ignition-proof for Class II environments.

2. Belt Alignment Monitoring - Our belt alignment products for bucket elevators include rub block door assemblies (3 models) and accompanying temperature sensors. The TT420S-LT temperature sensor features a stud mount adapter for easy attachment to a Rub Block Door Assembly. Sensor is 2-wire, loop-powered, and provides a 4-20 mA analog output. It is FM approved, dust ignition-proof for Class II environments.

3. Shaft Speed Monitoring - In this example shaft speed is being monitored by our ST420-DI shaft speed sensor and is mounted withEZ-18mm Mounting Bracket. This model is also 2-wire, loop-powered with 4-20 mA output and has FM Class II approval. We have many other options for shaft speed monitoring.